Why Proper Ventilation Is Critical for Your Roof’s Health

Proper roof vent installation is one of the most critical aspects of maintaining a healthy home and a long-lasting roof. A well-designed system allows your attic to breathe, protecting the structure from trapped heat and moisture that can silently destroy wood framing, insulation, and roof decking. Homeowners who pair correct ventilation with professional roof repair and replacement services consistently see longer roof lifespans and fewer unexpected issues. For those building a new home or replacing an aging roof, professional expert roofing services ensure your ventilation system meets local building codes and protects your investment. A well-ventilated attic regulates temperatures, reduces HVAC strain, and lowers energy bills.

Key Steps for Roof Vent Installation:

- Calculate Needs: Use the 1/150 rule (1 sq ft of ventilation per 150 sq ft of attic space).

- Choose Vents: Select balanced intake (soffit) and exhaust (ridge or static) vents.

- Mark & Cut: Carefully measure and cut openings in the sheathing, avoiding rafters.

- Install & Seal: Secure vents with roofing nails and apply sealant to prevent leaks.

- Balance System: Ensure a 50/50 split between intake and exhaust ventilation.

A balanced system is non-negotiable; without it, your roof won’t perform as designed, and you may void manufacturer warranties.

As Esteban Marin, I’ve installed and repaired roof vents across Loudoun County since 2001. I’ve seen how proper roof vent installation prevents thousands in moisture damage. Getting the ventilation right is the foundation of a durable roof.

Understanding Your Ventilation Needs Before You Start

Before cutting into your roof, understanding the principles of a balanced ventilation system and determining your home’s specific needs is paramount. Proper planning ensures your roof vent installation will be effective, compliant with local building codes in Leesburg, VA, and won’t compromise your roof’s integrity or warranty.

The Critical Role of a Balanced Ventilation System

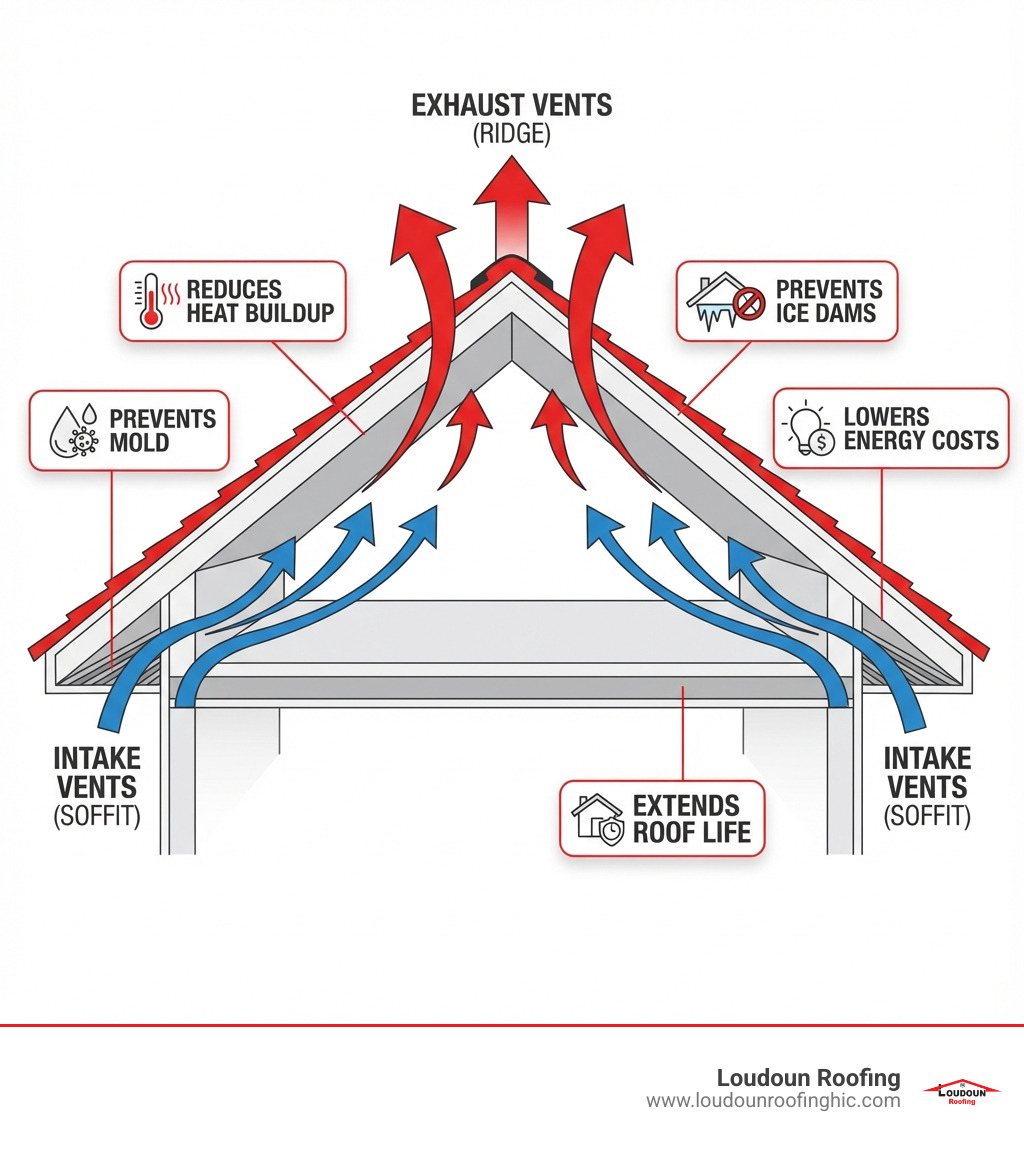

A roof ventilation system creates continuous airflow using the “stack effect,” where warm, moist air rises and exits, drawing in cooler, drier air from below. This natural convection is essential for your home’s health, especially in Northern Virginia’s climate.

Why Balance is Key:

A balanced system, with equal intake and exhaust, is required for optimal roof performance and is often a condition for manufacturer warranties. An unbalanced system, particularly with too much exhaust, can pull conditioned air from your living space, raising energy costs.

- Intake Vents (Soffit Vents): Located at the lowest points of the roof (under the eaves), these vents draw in cool, fresh air. Soffit vents are the most common and effective intake type. If your soffits are damaged, it can cripple your ventilation; our team can assist with roof soffit repair.

- Exhaust Vents (Ridge Vents): Positioned at the highest points (the ridge), these vents allow hot, moist air to escape. Ridge vents, which run along the entire peak, are highly effective.

Preventing Airflow Short-Circuiting:

To ensure a smooth flow from low to high, avoid mixing exhaust vent types or placing them at different heights. This prevents “short-circuiting,” where one exhaust vent pulls air from another instead of from the intake vents.

Types of Roof Vents: Exhaust and Intake

Choosing the right vent is a critical step in roof vent installation. Vents are categorized as passive (using natural airflow) or active (using mechanical force).

| Vent Type | Cost | Effectiveness | Climate Suitability | DIY-Friendliness |

|---|---|---|---|---|

| Static Vents | Low | Moderate (passive) | All (less effective in still air) | High |

| Ridge Vents | Moderate | High (passive, continuous) | All | Moderate |

| Turbine Vents | Moderate | High (wind-driven) | Windy areas | Moderate |

| Powered Vents | High | Very High (thermostat-controlled) | All | Low (Pro-only) |

| Soffit Vents | Low | High (intake, passive) | All | Moderate |

- Static Vents: Simple, non-motorized boxes installed near the ridge that allow hot air to escape. Their low cost and simple design make them a popular DIY option, though they are less effective on still days.

- Turbine Vents: Also known as “whirlybirds,” these active vents use wind to spin a turbine that pulls air from the attic. They are highly effective in windy areas but require periodic maintenance.

- Powered Vents: These are thermostat-controlled electric fans that provide powerful, consistent ventilation regardless of weather. They are highly effective but require professional electrical installation.

- Soffit Vents: These passive intake vents are installed under the eaves to supply fresh air, forming the foundation of a balanced system.

- Gable Vents: Installed in the gables of a home, these can act as intake or exhaust but rely on wind and are best used with soffit vents.

- Drip-Edge Vents: A less common intake vent installed at the eaves. The NRCA advises against them in cold climates due to ice dam risks.

How to Calculate Ventilation Requirements

Determining the correct amount of ventilation for your attic is crucial for effective roof vent installation. It’s not a one-size-fits-all scenario, as factors like attic size, vapor barriers, and roof pitch all play a role.

The 1/150 Rule & 1/300 Rule

These are the industry-standard rules for calculating Net Free Area (NFA), which is the unobstructed area through which air can pass.

- 1/150 Rule: You need one square foot of NFA for every 150 square feet of attic floor area. This rule applies if there is no vapor barrier on your attic floor.

- 1/300 Rule: If your attic floor has a vapor barrier, you will need one square foot of NFA per every 300 square feet of attic floor area. This is often the minimum requirement for local building codes.

In both cases, the total NFA should be split evenly: 50% for intake vents and 50% for exhaust vents.

Attic Square Footage

To calculate your attic’s square footage, simply measure the length and width of your attic floor and multiply them. For example, a 20 ft x 30 ft attic is 600 sq ft.

Roof Pitch Adjustments

If your roof slope is greater than average (typically 6:12), you will need more ventilation to reflect the extra volume of attic space:

- Calculate 20% more NFA for 7:12 to 10:12 pitches.

- Calculate 30% more NFA for pitches 11:12 or greater.

Net Free Area (NFA) Calculation

Every vent has a published NFA rating. You’ll need to select enough vents (both intake and exhaust) so that their combined NFA meets your calculated requirements. It’s generally better to have slightly more intake ventilation than too little. Many homes undercalculate the amount of intake needed, so err on the side of having more.

For a deeper dive into these calculations, you can refer to resources like AirVent.com’s attic ventilation calculations guide.

Essential Tools and Materials for Installation

Before starting on any roof vent installation project, gathering the right tools and materials is crucial. This not only ensures efficiency but, more importantly, safety.

Here’s a comprehensive list of what you’ll likely need:

- Safety Harness: Absolutely essential for fall protection when working on a roof, especially for homeowners in Loudoun County. We prioritize safety above all else.

- Ladder: A sturdy, properly secured ladder for safe roof access.

- Pry Bar: For carefully removing shingles.

- Utility Knife: For cutting shingles and other roofing materials.

- Circular Saw or Reciprocating Saw: For cutting openings in the roof deck. A keyhole saw or saber saw can also be used for circular cuts.

- Drill: For pilot holes and securing vents.

- Caulking Gun: For applying roofing sealant.

- Roofing Sealant / Cement: High-quality, waterproof sealant (e.g., asphalt plastic cement, non-petroleum sealant as per manufacturer).

- Galvanized Roofing Nails: Corrosion-resistant nails for securing vents and shingles.

- Measuring Tape & Chalk Line: For accurate measurements and marking.

- Hammer: For nailing.

- Pencil or Marker: For marking cuts.

- Safety Glasses/Goggles: To protect your eyes from debris.

- Work Gloves: For hand protection.

- Dust Mask: If cutting into dusty materials.

- The Vents Themselves: The specific intake and exhaust vents you’ve chosen.

- Flashing (if not integrated with vent): To ensure a watertight seal.

- Attic Baffles (for soffit vents): To prevent insulation from blocking airflow.

- Shingles (matching existing): If replacing damaged ones or for covering ridge vents.

A Homeowner’s Guide to Roof Vent Installation

The roof vent installation process varies by vent type, but the core principles of safety, precise cutting, and thorough sealing remain constant. Following a step-by-step approach is key to a successful, leak-free installation that protects your roof decking, rafters, and shingle layers while ensuring proper waterproofing.

Safety First: Essential Precautions for Working on a Roof

Working on a roof is dangerous. For any DIY roof vent installation, these precautions are non-negotiable:

- Fall Protection: Always use a properly anchored safety harness.

- Ladder Safety: Use a stable ladder that extends three feet above the eave.

- Weather: Only work on dry, clear days with minimal wind.

- Footwear: Wear non-slip, soft-soled shoes for traction.

- Eye Protection: Use safety glasses when cutting, drilling, or nailing.

- Electrical Hazards: Be aware of wiring in the attic and roof. Turn off power if necessary.

- Tool Safety: Handle tools carefully and keep the work area clear.

If you are uncomfortable with heights or complex roofing tasks, call a professional. Our team is equipped for safe project execution, including complex storm damage repair.

Installing Soffit Vents for Proper Air Intake

Soffit vents provide essential intake air. Installation involves these key steps:

- Mark Placement: From underneath, mark the vent location on the soffit, centered between rafters.

- Cut Openings: Cut a hole slightly smaller than the vent unit. For continuous vents, cut a long, narrow slot.

- Secure Vents: Install the vent with screws per the manufacturer’s instructions, ensuring it is flush and secure.

- Clear Airflow: From inside the attic, confirm insulation is not blocking the vent opening.

- Install Baffles: Add attic baffles (rafter vents) to create a permanent channel for air, preventing insulation from blocking the soffit.

Step-by-Step Static Roof Vent Installation

Static vents are a popular choice for their simplicity. This is a general guide for their roof vent installation:

- Mark from the Attic: From inside the attic, drive a nail up through the sheathing to mark the vent location. Place it 24-36 inches from the ridge and centered between rafters to avoid obstructions.

- Confirm Location: On the roof, the nail serves as your pilot hole, confirming a clear spot.

- Cut the Opening: Use the manufacturer’s template to trace the opening. Cut through the sheathing with a reciprocating saw, being careful not to overcut.

- Remove Shingles: Use a pry bar to gently remove shingles where the vent flange will sit. The flange must slide under the uphill shingles and over the downhill ones.

- Apply Sealant: Apply a bead of roofing sealant around the hole on the roof deck and on the underside of the vent’s flange.

- Position the Vent: Slide the top of the flange under the upper shingles and lay the bottom over the lower shingles. Center it over the hole.

- Nail the Vent: Secure the flange to the roof deck with galvanized roofing nails through the pre-drilled holes.

- Seal and Finish: Cover all nail heads and the flange edges with sealant. Trim and reinstall the surrounding shingles for a watertight finish.

Step-by-Step Ridge Vent Installation

Ridge vents provide highly effective, continuous exhaust. Installation is common during a full roof replacement but can also be retrofitted.

- Cut the Ridge Slot: Mark and cut a continuous slot along the ridge, typically 1-1.5 inches down from the peak on each side. Set your saw depth to cut only the sheathing, not the rafters.

- Install Vent Sections: Lay the ridge vent sections end-to-end along the slot, starting from one side of the roof.

- Connect and Secure: Apply sealant to the joints between sections and secure them to the roof deck with galvanized roofing nails, following the manufacturer’s pattern.

- Install End Caps: Seal the ends of the ridge vent run with manufacturer-provided end caps to prevent weather and pest entry.

- Install Cap Shingles: Cover the entire ridge vent with ridge cap shingles, nailing through the vent and into the roof deck. Seal all exposed nail heads for a final watertight layer.

Pro Tips for a Durable and Watertight Installation

Proper sealing and adapting to your specific roof are what separate an amateur job from a professional one. These considerations are critical to prevent water intrusion and ensure the longevity of your roof in Northern Virginia. A poorly installed vent is a prime candidate for a roof leak, which can lead to significant damage. For assistance with any leaks, our team offers specialized roof leak repair services.

The Secret to a Watertight Seal Around Your New Vent

A watertight seal is the single most important aspect of any roof vent installation. Without it, you’re essentially creating a new leak point on your roof.

- Roofing Cement vs. Sealant: Always use high-quality roofing cement (asphalt-based) or a manufacturer-approved sealant (often non-petroleum based for certain plastic vents). Roofing cement is excellent for sealing under flanges and over nail heads for asphalt shingles. Always check the vent manufacturer’s recommendations, as some plastic vents can be damaged by petroleum-based products.

- Flashing Integration: Most roof vents come with an integrated flashing system. Ensure this flashing is properly incorporated with your existing shingles. The vent’s flange should slide under the uphill courses of shingles and lie over the downhill courses. This “shingle-over-shingle” method directs water over the vent, not into it.

- Tucking Flange Under Uphill Shingles: This is non-negotiable. Water flows downhill. If the vent’s flange is on top of the uphill shingles, water will pool and eventually seep under. Carefully lift the shingles above the vent to slide the top edge of the vent’s flange underneath.

- Sealing All Edges and Fasteners: Apply a continuous bead of sealant or roofing cement around the entire perimeter of the vent’s flange where it meets the roof. Pay special attention to any exposed edges and, crucially, cover every single nail head with a generous dab of sealant. This ensures no water can penetrate the roof through fastener holes. This diligent approach is also critical for effective roof and window flashing.

Adapting Your Roof Vent Installation for Different Materials

The roof vent installation process varies significantly by roofing material.

- Asphalt Shingles: As the most common material in Northern Virginia, installation involves lifting and cutting shingles to integrate the vent’s flashing, maintaining the shingle overlap for water runoff. Roofing cement is the standard sealant.

- Metal Roofing: This requires special tools to cut panels without damage. Vents for metal roofs use specific gaskets and flashing to match panel profiles. Self-tapping screws with neoprene washers are used, and sealants must be metal-compatible to prevent corrosion.

- Tile Roofs: Installation is complex, requiring careful removal and cutting of tiles. Vents are designed to match the tile profile, and elaborate flashing is often needed. This work requires extreme care to avoid breaking tiles.

- Fasteners and Sealants: Use fasteners and sealants appropriate for the specific roofing material. Screws are common for metal and tile, while nails are used for shingles. Always check for sealant compatibility to prevent material degradation.

New Construction vs. Retrofitting Vents on an Existing Roof

The approach to roof vent installation differs between new builds and existing roofs.

-

New Construction (Open Sheathing): Installation is simpler on an exposed roof deck. Vents are installed directly onto the sheathing before the underlayment and shingles, allowing for perfect placement and a seamless, watertight seal from the start.

-

Retrofitting (Existing Roof): This is more complex and labor-intensive. It involves carefully removing existing shingles to integrate the vent, which risks damaging older materials. Matching shingle color and wear can be difficult. When cutting the deck, the existing underlayment is also cut and must be properly resealed. Achieving a perfect seal on an older roof requires significant skill, making it a job best left to a professional roofer in Loudoun County.

Frequently Asked Questions about Roof Vent Installation

How many roof vents do I need?

The number of vents depends on your attic’s square footage and the Net Free Area (NFA) of the vents you choose. The general rule for homes without a vapor barrier is one square foot of NFA for every 150 square feet of attic floor space, split evenly between intake and exhaust. If a vapor barrier is present, this ratio can be adjusted to one square foot of NFA for every 300 square feet of attic floor space. Remember to factor in adjustments for roof pitches greater than 6:12 (add 20-30% more NFA).

Can you have too much roof ventilation?

It is difficult to have too much total ventilation, but it is critical that the system is balanced. Having significantly more exhaust than intake can cause vents to pull conditioned air from inside the home, leading to energy loss. It’s better to have slightly more intake than exhaust, as this ensures that all exhausted air comes from outside the conditioned space. The goal is always a balanced 50% intake to 50% exhaust ratio for optimal performance.

What is the best placement for roof vents?

Exhaust vents (like static or ridge vents) should be placed as close to the roof’s peak as possible to allow hot, moist air to escape naturally as it rises. Intake vents (like soffit vents) must be installed at the lowest part of the roof, such as under the eaves, to draw in cooler, fresh air. This creates the necessary airflow path from bottom to top, facilitating efficient heat and moisture removal. All exhaust vents within a common attic area should ideally be at the same height to prevent short-circuiting.

Conclusion

Proper roof vent installation is a vital project that significantly improves your home’s energy efficiency, prevents moisture damage, and extends the life of your roof. While some installations can be a DIY task for experienced individuals, the inherent risks of working at height and the critical need for a watertight seal often make it a job best left to professionals. A single mistake can lead to costly water damage and compromise your roof’s warranty.

For a flawless installation that guarantees peace of mind and protects your home for years to come, trust the experts at Loudoun Roofing. Our team has the experience and expertise to ensure your ventilation system is perfectly balanced and watertight, custom to the specific needs of your Northern Virginia home. If you are comparing options for roofing services in Loudoun County, our licensed team can inspect your current system, recommend the right mix of intake and exhaust vents, and handle everything from minor upgrades to full roof replacement in compliance with local building codes.